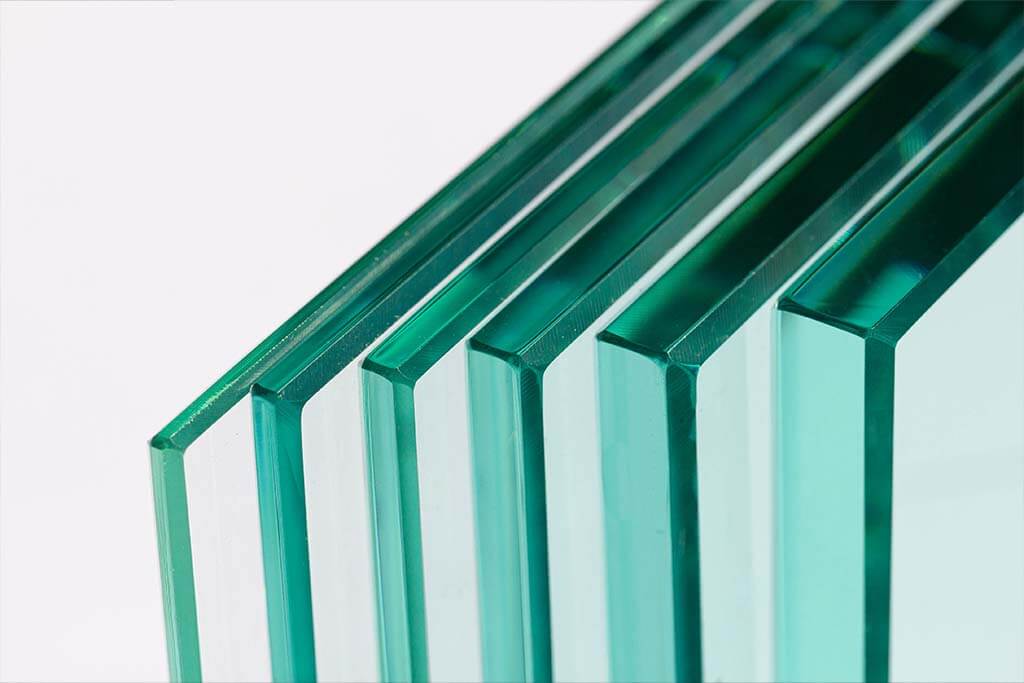

Most of the glass panes we see today in all their applications are float (from the English word floating). In fact, glass is named after the process required to manufacture it. The raw materials – such as silica sand, soda ash, lime, potash and recycled glass – are melted together in a furnace. The molten glass composition is poured into a molten tin chamber. Since glass is lighter than tin, it floats on top, forming a uniform layer on the surface. The glass is then subjected to a cooling process during which it is stabilized and hardened.

The main properties of transparent float glass include:

High light transmittance: the most remarkable advantage of float glass is its smooth, clean surface, without streaks or bubbles. Its light transmission rate is usually around 85-90%.

Chemical inertness: transparent float glass is chemically non-reactive and impermeable, so it is suitable for applications involving contact with other substances such as food and beverages. So glass is an inert, non-porous material.

Recyclable: transparent float glass can be recycled many times, so it is environmentally friendly.

Durability: Clear float glass can be chemically toughened to achieve greater hardness and scratch resistance.

Due to its strength and excellent clarity, transparent float glass is a common type of glass for windows and glass containers, especially in the food and beverage industry. The most popular form of transparent float glass is soda lime glass, named after its greenish tint. This type of glass makes up about 90% of all manufactured glass. Clear glass is also a preferred recycled material because it can be melted and softened repeatedly without losing its integrity. The resistance to bending fracture has the following rates:

40 Newton/mm2 (= 40MPa) for ordinary glass

120 – 200 Newton/mm2 (= 120MPa) for tempered glass, depending on its thickness, grinding, holes, notches, etc.

Elasticity: glass is a completely elastic material. It does not show permanent deformation until it breaks. But it is fragile and will break without warning if exposed to excessive tension.

Thermal characteristics

Linear expansion: expressed by a coefficient that measures the area (elongation) for a temperature difference of 1oC. This factor is generally valid for temperatures from 20 to 300 0C.

The coefficient of linear expansion of glass is:

9 X 10-6 m/mk (= 0. 009m)

Example:

A 2 m (2,000 mm) long glass exposed to a temperature rise of 30 0C will elongate by:

2 x 9 x 10-6 x 30 =0. 54 mm (half a millimetre)

Thermal Conductivity & Thermal Tension: The thermal conductivity (λ) of glass is low (λ=1. 0 W/(m. K) approximately). A natural consequence of this is that internal stresses are created when there are differences in the temperature of the glass pane between one part of the pane and another.

(This usually occurs in solar control glass and often leads to breakage due to thermal shock)

The most well-known applications of Transparent Glass are in: