Tempered or fired glass is a type of safety glass that has undergone controlled heat or chemical treatments, increasing its strength compared to normal glass. The hardening leads the outer surface of the glass pane to compressive stress and the inner surface to increased tensile forces. When the tempered glass breaks, these forces are released, causing it to shatter into small granular pieces instead of jagged fragments like ordinary unfired glass. These granular pieces are less likely to cause injury.

Safety Applications of Thermally Hardened Glazing

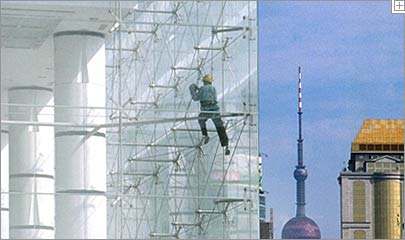

Tempered glass is used in various applications and more specifically where security needs are increased:

– Transport media (car windscreens, airplane windscreens, train windscreens, ship windows, etc. )

– Raised floors and stairs

– Shop windows

– Terrace

– Roofs

– Showers, with or without frame

– Point-support glazing panels

– Folding doors (harmonicas)

– Frameless shorts for furniture

– Balconies, parapets (always in combination with additional triplex treatment, if there is no support frame)

Tempered glass is about four times stronger than ordinary unfired glass. The large contraction of the inner layer during tempering causes compressive stresses on the glass surface that are balanced by tensile stresses in the glass body. The 6 mm thick fully toughened glass shall have a minimum surface compression of 69 MPa (10 000 psi). To be considered safety glass, the surface compressive stress must exceed 100 megapascals (15,000 psi). As a result of the increased surface pressure, when the glass is broken it becomes small rounded pieces (something like “rice”).

Thermally reinforced glass (SECURIT) focuses on its enormous resistance to breakage (400% more resistant than ordinary glass), essentially protecting against the adverse effects of the shattering of ordinary glass.

All the properties and most of the physical characteristics of the glass remain unchanged after heat treatment. Thus, the thermal conductivity, light reflection/permeability, energy absorption/reflection/permeability, surface expansion, elasticity index, sound insulation and weight remain the same.

However, some other characteristics are dramatically changed for the better, for example :

Impact resistance to deformable objects (human body) (+400%)

Tensile strength (+300% of ordinary glass)

Resistance to temperature differences (+500% of ordinary glass)

In summary, thermally toughened safety glass (which for the sake of brevity we will call roasted) has some special properties, in addition to those of ordinary glass:

They show 4 to 5 times increased mechanical strength, compared to the corresponding thickness of single glass panes.

If the breaking point is exceeded, then they are shattered into small pieces that are harmless to bodily integrity.

They exhibit very high resistance to temperature changes (up to 290°C), which makes them immune to thermal shocks (from non-artificial means).

The glass panes, after being cut to the desired dimensions from the large glass plate, arrive at the heat treatment unit (securit furnace). These panes are precisely measured, their edges have already been ground, and any holes and notches have already been made. These pieces are heated to 600 ⁰C using controlled and uniform heating and then rapidly cooled using cold air, and finally “quenched” by quickly returning them to room temperature. This “quenching” or, in professional terms, “expansion” causes the surface of the glass to cool faster than the center of mass, which creates a constant tensile force on the glass. The tensile stress increases from the surface of the glass pane, which is under compressive stress, to the center of the piece. This stress structure gives the glass pane its extraordinary potential and also explains why all treatments have to be done on it in advance. If, for example, we try to drill somewhere in the glass after it has been heat treated, the whole piece will shatter. The reason is that the drilling process breaks or disrupts the stress structure, which causes the glass to be destroyed. Voltage bands are visible under polarized light and can be seen at certain angles as colored visual effects.

The company VLAVIANOS S. A. , with its state-of-the-art mechanical equipment, manufactures thermally toughened glass panes, providing all the certifications required by the regulations. (EN 12150-3)